Careers

Do you want to solve global energy challenges for future generations?

News

Fourth quarter results 2023: Solid performance, positioning for long-term profitable growth

News

Aker Solutions wins Hafslund Oslo Celsio CCS FEED

Featured news and stories

What we do

Accelerate a transition to sustainable energy

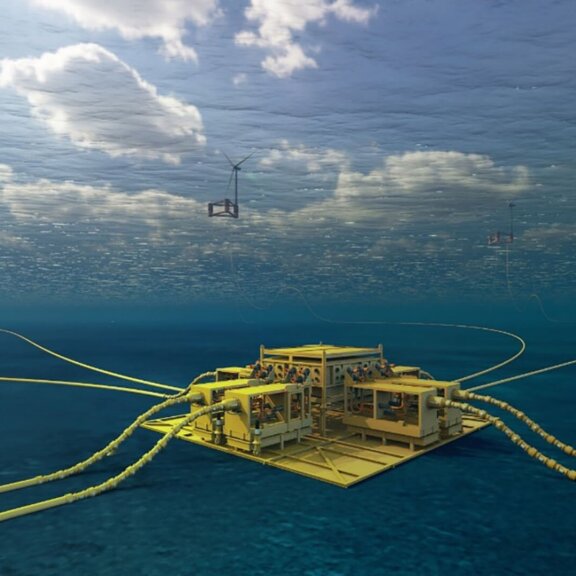

Powered by digital technology, strategic partnerships and a strong culture of solving problems, we deliver complex energy projects in a safe, predictable and sustainable way.

About us

Learn more about Aker Solutions

Aker Solutions delivers integrated solutions, products and services to the global energy industry. We enable low-carbon oil and gas production and develop renewable solutions to meet future energy needs.