Additive Manufacturing

Greater design flexibility, lower costs, shorter lead times and improved sustainability are the key advantages that 3D printing and additive manufacturing techniques can offer on a wide range of projects.

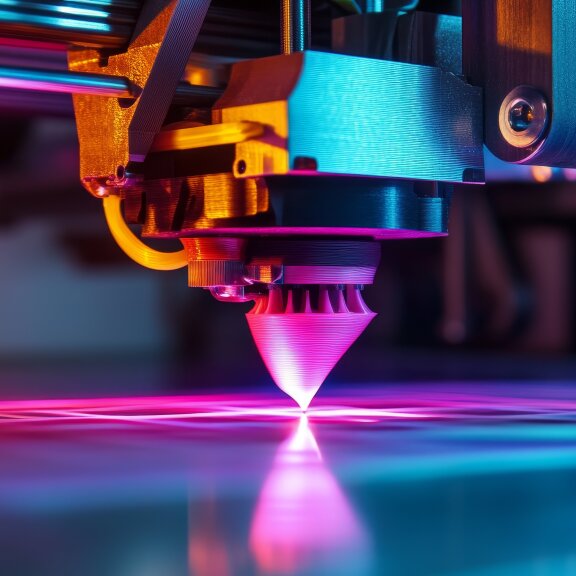

Additive manufacturing – the basics

Additive manufacturing is the process of creating three-dimensional components layer by layer using 3D digital designs.

This new production technique gives:

- greater flexibility in material choice from polymers to metals or even ceramics and enables multi-material printing

- increases customizability for complex geometries

- increases design freedom by removing some of the limitations of traditional fabrication processes

- enables multiple components to be combined in a single unified part

- facilitates repair or upgrading parts or equipment, rather than replacement

Improving asset economics through digital inventories

Today, production based on 3D printing relies on digital tools, such as digital inventories or warehouses for 3D models, material specifications, and other data that enable on-demand production for rapid procurement and supply of new parts.

On-demand assessment for faster, more flexible decision making

Digital inventories allow discipline experts to quickly browse through past cases, then simulate contributions and assess potential production challenges.

Optimized 3D modelling and prototyping

Easy access, reuse and adaptation of existing models across an entire project portfolio can mean less time spent on design and 3D modelling. Additive manufacturing also allows rapid prototyping to ensure 100% fitness for purpose.

On-demand manufacturing

The ability to 3D print on-demand, based on pre-existing 3D models, can reduce supply lead time from months to days, reducing the need for large spare part inventories and cutting warehousing costs.

Optimize environmental footprint

Sustainability benefits include local sourcing and optimized designs that reduce the amount of material used and waste generated. Additive manufacturing contributes positively to emissions reduction targets and decarbonization goals.

Contact

ADDMO - Additive Manufacturing Operations Center

addmo@akersolutions.com