Engineering the future of energy with additive manufacturing

Discover how 3D printing transforms energy operations—faster, smarter, and more sustainable.

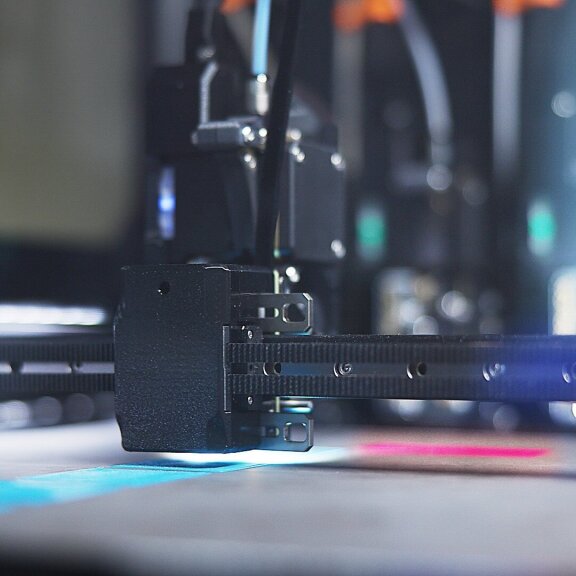

3D printing—also known as additive manufacturing—builds parts layer by layer from a digital model. This precision process enables complex geometries, custom designs, and optimized material properties, transforming how components are made.

Why additive manufacturing matters for energy

Additive manufacturing delivers lower costs, faster turnaround, and minimal waste—while unlocking design freedom for high-performance energy components.

From subtractive to additive

Traditional manufacturing removes material to shape parts. Additive manufacturing adds material only where needed, reducing waste, enabling rapid prototyping, and supporting local production for shorter supply chains.

AM basics

Additive manufacturing creates three-dimensional components, layer by layer, based on a 3D model. This changes how parts are produced, and how components are combined into parts:

- Print polymers, metals, even ceramics

- If you can 3D model it, you can 3D print it

- AM makes complex geometries simple

- Efficient for one-of-a-kind / one-at-a-time production

- Print multi-component parts in a single process

- Enables repair and upgrades of existing equipment

Five advantages of additive manufacturing

Additive manufacturing is driving innovation and efficiency in the energy sector, contributing to more sustainable and cost-effective solutions.

At the Aker Solutions additive manufacturing operations centre, we use 3D printing to develop advanced components and systems more safely and efficiently, to meet the demands of modern energy operations.

Cost, time and quality improvements

For the energy sector, 3D printing offers five clear advantages:

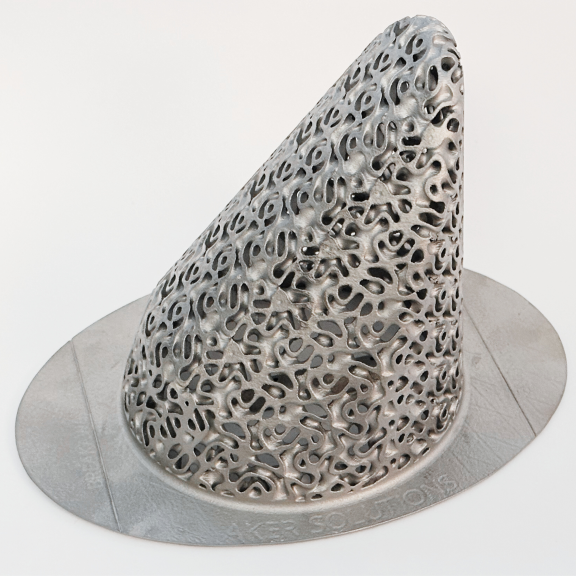

- What AM enables: Complex geometries, internal lattice structures, and optimized flow channels that improve performance and reduce weight. Components, which were once assembled from multiple parts, can now be printed as a single piece, reducing failure points.

- Why it matters: Offshore energy systems demand high-performance components, often in tight spaces. AM makes it possible to tailor parts to specific environments and performance goals.

- What AM enables: Fully customizable parts without the need for expensive retooling. Each component can be uniquely tailored for specific installations or operational needs.

- Why it matters: Whether retrofitting a worn or damaged part on an aging installation or adapting to new regulations, the ability to modify equipment on demand saves both time and money. Traditional manufacturing can't match the responsiveness AM offers.

- What AM enables: Precise material usage with minimal waste. In addition to its unique ability to combine mateials, additive processes virtually eliminate waste, so high-value materials like titanium or 316L stainless steel can be used efficiently.

- Why it matters: Reducing material waste offers cost and sustainability benefits helping the energy industry is to deliver on its decarbonization targets. 3D printing helps reduce emissions across the supply chain.

- What AM enables: Rapid prototyping and iteration, combined with local, on-demand manufacturing.

- Why it matters: Unexpected downtime due to part failure can be costly. With 3D printing, critical components can be produced near the point of need—greatly reducing shipping times and logistics challenges.

- What AM enables: Eliminates tooling costs for small batches and complex parts. More cost-efficient for custom and spare-parts production.

- Why it matters: Traditional manufacturing is optimized for mass production. But in the energy sector, many parts are custom, low-volume, or even obsolete. With AM these precision parts are 3D printed, reducing inventory and warehousing needs, and lowering the overall cost of supply.

Engineering the future at ADDMO

Our Additive Manufacturing Operations Center (ADDMO) delivers end-to-end solutions—combining innovation, digitalization, and sustainability to meet the demands of modern energy operations.

Our services

- On-demand assessment: Feasibility evaluations and proactive maintenance strategies.

- AM engineering expertise: Topology optimization, thermal simulation, and EcoLense LCA for carbon tracking.

- Smart digitalization: Virtual warehouses and just-in-time manufacturing to reduce costs.

Driving sustainability through innovation

By integrating our EcoLense LCA system, we quantify emission reductions and track the carbon impact of every component—helping the energy industry deliver on decarbonization targets.

What should you do when something breaks?

Contact ADDMO@akersolutions.com. Geir Anders Berge explains why 3D printing is a smarter faster and more sustainable solution and how this can transform maintenance decisions.

Ready to transform maintenance, modification and operations?

Request additive manufacturing services today and unlock efficiency, flexibility, and sustainability.