Preventing offshore downtime | How additive manufacturing solved deck drain challenges

Challenge

Weather deck drain boxes were frequently clogged due to the lack of proper strainers. Some boxes had temporary strainers glued in place, while others relied on fine grating installed beneath the deck grating. These improvised solutions were both inconsistent and unreliable, leading to increased maintenance and potential safety risks.

- On Troll A, this recurring issue had begun to affect operations

- On Troll B, robust, cost-effective floor strainers suitable for harsh offshore conditions were urgently required.

Complication

Commercially available strainers did not fit the unique geometry of the drain boxes, and blockages could lead to water accumulation and hinder deck operations. Offshore downtime had to be minimized, however, traditional procurement routes were slow.

Why ADDMO?

- No standard solution

- Customisation required

- Time sensitive

Our solution

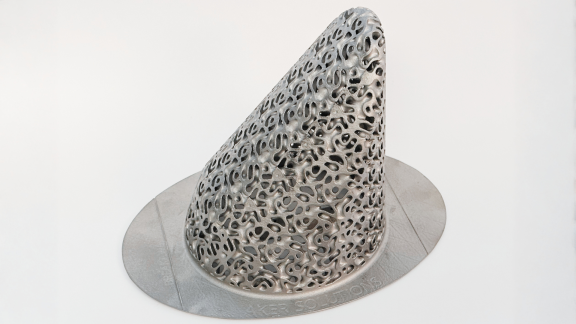

The ADDMO team custom-designed deck strainers, precision matched to operational needs, and produced them locally, using additive manufacturing. Our approach had three key elements:

The original tool was 3D scanned and recreated as a 3D model. A hole was added to allow the wrench to be hung near the valve for easy access.

The wrench was engineered at ADDMO and stored in the digital warehouse for on-demand production. Design approval and fabrication were completed within days, minimizing lead times and logistics costs.

Produced using durable, corrosion-resistant material suitable for offshore conditions, ensuring longevity and reliability.

Benefits

- Enhanced reliability | Precise design and material selection improved performance.

- Universal solution | Adaptable to variations in deck-drainpipe angles; future modifications possible.

- Cost efficiency | Reduced maintenance costs compared to conventional methods.

- Faster manufacturing | Additive manufacturing shortened production timelines significantly.

- Lower service delivery costs | Local production cut logistics expenses.

Key takeaways

- Additive manufacturing delivers real-world impact: faster, smarter, and more sustainable solutions for offshore energy operations.

- Local production minimises downtime and total cost.

- Material innovation enhances reliability in harsh environments.

Reach out to our experts