How Aker Solutions makes digital and AI count for customers

Digitalization is entering a new phase. Technology hype has hardened into a search for scalable value—for shareholders and customers—based on measurable outcomes.

Our digital and AI initiatives deliver real gains by unlocking marginal business cases, accelerating project execution, and maximizing performance while reducing emissions.

Unlocking opportunities in early design

Early-phase decisions often determine whether a project moves forward. Entr consultants use advanced models and AI algorithms to screen scenarios, analyze benchmarks, and identify key cost drivers. Building on decades of real-world experience, this lays the groundwork for integrated operations and large-scale automation.

- Studies reveal potential savings—unlocking business cases that would otherwise be unviable.

- AI produces crucial insights earlier and faster

- Customers make confident decisions that reduce risk.

Read more: Entr case studies

Executing projects faster reduces costs

From small to large projects, digital and AI solutions streamline our engineering workflows and increase transparency.

New tools connect workers with engineering systems, increasing precision and efficiency during construction and completion. Meanwhile, automated supply chains support effective nonstop production. Digitalization is impacting all disciplines and project phases, cutting manhours and reducing errors. Engineering hours have dropped by 6-8% on recent projects.

- Faster delivery and lower total cost of ownership for our customers

- Faster project turnaround with AI optimized scaffolding design and paint masking

- Better change management as augmented reality brings 3D models into the yard and links these to interactive work instructions

- Faster completion using AI and image recognition in the yard to spot gaps between the model and the real-world condition

- Faster inspections by remote and hybrid QC teams update workflows faster and reduce errors.

Maximizing uptime and extending life-of-field

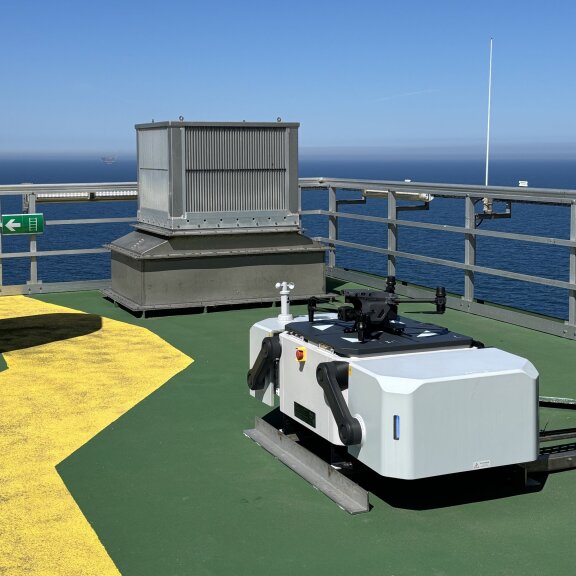

New digital services gather and contextualize data for faster, smarter decision-making on brownfield projects. We use innovative technologies like autonomous drones and industrial robots—integrating them into digital workflows and feeding data into digital twins.

- To support unmanned offshore operations, we are enabling remote inspection using autonomous robots and drones—we are BVLOS certified to the fly drones remotely offshore and onshore.

- Remote inspection reduces cost, risks, and emissions while maximizing uptime and asset performance. A pilot, on Edvard Grieg, delivered inspection data in real time to our control center 350 kilometers away in Stavanger.

- Savings (vary by location) come from reduced manhours, lower emissions and less travel time, plus in turnaround of data analysis.

Enablers that make it possible

Behind these outcomes is a secure, AI-ready data foundation, digitally competent teams and strong partnerships. It’s a model based on shared value.

Our partnerships within the Aker Digital Alliance (ADA) and with leading technology providers ensure customers benefit from proven, industry-grade solutions that integrate seamlessly with their systems.

We take a collaborative approach, working with customers to co-design and co-implement solutions, ensuring faster adoption and interoperability across platforms and data ecosystems.

By shifting the focus from time and materials to shared value creation, we can offer commercial frameworks aligned to customer success. These include outcome-based models tied to speed, cost efficiency and uptime.

People are essential to drive transformation. We are continuously upskilling teams across engineering, supply chain, and project management to embed digital and AI competencies into every role. This ensures our workforce can both lead change and leverage new technologies.

From effort to outcomes

Real and lasting value for customers lies in digital solutions that connect across the asset lifecycle as one integrated ecosystem. By embedding AI and digital capabilities from concept to completion and throughout the lifecycle, we support our customers’ focus on viability, reliability and uptime.

Explore our digital and AI initiatives