NOA and Fulla – Delivering on the Promise of Digital Transformation

In 2020, Equinor and Aker BP reached an agreement on the coordinated development of the NOAKA area in the Norwegian North Sea. The region is comprised of several reservoirs and is estimated to hold total recoverable resources in excess of 500 million barrels of oil equivalent (boe).

As part of the agreement, Aker BP will operate NOAKA’s North of Alveheim (NOA) and Fulla licenses, while Equinor will operate the Krafla license. LOTOS Exploration and Production Norge AS is partner in the NOA and Fulla licenses.

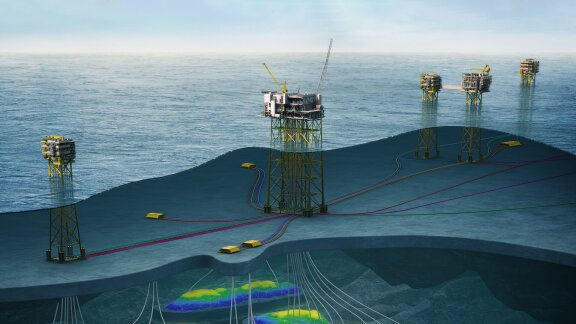

Current field development plans include construction of a main processing platform operated by Aker BP in the south and an unmanned processing platform operated by Equinor in the north, and several satellite platforms and tiebacks. The two developments will be mutually dependent on a number of shared utilities, including oil and gas export infrastructure and electrical power from shore.

Aker Solutions was awarded the full field development pre-FEED contract for NOA and Fulla by Aker BP. NOA Fulla is an alliance project, and Aker Solutions contributes as part of the fixed facilities alliance and subsea alliance. The scope of work includes design, engineering, and construction studies of both the topsides facilities and the subsea production system (SPS). The contract builds on the strong relationship between the two companies and aims to define a new standard for field development and operations through the extensive use of digitalization.

The transformation is being driven by the ADA project, a joint initiative between Aker Solutions, Aker BP, Aize, and Cognite.

To streamline project development, Aker Solutions will together with the subcontractors Cognite and Aize develop a digital twin that will be populated with the physical assets from the processing platforms and SPS.

Development of the digital twin will open up opportunities for significant cost and schedule savings in the engineering, procurement, and construction phase of the project by enabling advanced capabilities, such as exchange of data and 3D drawings instead of documents, automation of engineering and construction drawings and construction optimization. It also aims at facilitating implementation of a low-manning concept when the facility reaches the operational phase.

Facility start-up is scheduled for 2027.